What is Co-extruded WPC Flooring?

Wood Plastic Composite (WPC) has revolutionized the outdoor decking industry, providing a durable and sustainable alternative to traditional wood. Within the realm of WPC, Co-extruded technology has emerged as a cutting-edge method, enhancing the material’s performance and aesthetic appeal. In this article, we will talk about the characteristics and advantages of co-extruded WPC, shedding light on why it has become a preferred choice for outdoor applications.

Understanding the Meaning of Co-extrusion

Co-extrusion is a sophisticated manufacturing technique, which combines two or more materials simultaneously, yielding a composite with distinct layers. In WPC, this process integrates an outer cap layer alongside the core material. Engineered for superior performance, the outer layer shields the core, augmenting the durability and aesthetics of WPC products like wood plastic composite flooring. This method ensures that the composite achieves optimal strength, resilience, and visual appeal, making it ideal for various applications, especially in outdoor settings where weather resistance and longevity are paramount. By leveraging the advantages of co-extrusion, manufacturers can produce WPC materials that surpass traditional alternatives in terms of durability, maintenance, and overall quality. As the demand for high-performance building materials grows, co-extrusion remains a pivotal technique in enhancing the capabilities and versatility of WPC products in the construction and design industries.

Characteristics of Co-extruded WPC Flooring

Made with two layer, the co-extruded wood plastic composite is different from the standard WPC board. Here are some characteristics that co-extruded wood plastic composite flooring has:

- Multi-Layer Structure

Co-extruded WPC features a multi-layer structure, combining different materials for specific purposes. The outer layer is often comprised of high-performance polymers, providing superior protection against elements like UV rays, moisture, and scratches. The inner core, made from a wood-plastic composite, maintains the structural integrity and stability of the material.

2. Enhanced Durability

The outer layer acts as a shield, offering heightened durability compared to traditional WPC. This added layer of protection makes co-extruded WPC highly resistant to fading, staining, and wear over time. As a result, it boasts an extended lifespan, even in challenging outdoor environments.

3. Improved Aesthetics

Co-extruded technology allows for the incorporation of intricate and realistic wood grain patterns on the outer layer, providing a natural and authentic appearance. The advanced manufacturing process enables a level of detail that mimics the look of traditional wood, making co-extruded WPC a visually appealing choice.

4. Color Retention

The outer shell of co-extruded wood plastic composite flooring is formulated to resist color fading caused by prolonged exposure to sunlight. This characteristic ensures that the decking retains its vibrant color and aesthetic appeal over the long term, maintaining a fresh and attractive appearance.

Advantages of Co-extruded WPC Flooring

Compared with normal WPC board, the co-extruded WPC board has performed better in different aspects.

1. Longevity and Performance

The multi-layered structure of co-extruded wood plastic composite significantly enhances its overall performance and longevity. The outer layer acts as a robust barrier, ensuring the core material remains protected from environmental factors and daily wear and tear.

2. Weather Resistance

Co-extruded WPC is engineered to withstand diverse weather conditions, making it an ideal choice for outdoor applications. It resists the detrimental effects of sunlight, rain, snow, and fluctuating temperatures, maintaining its structural integrity and appearance.

3. Environmentally Friendly

Like traditional WPC, co-extruded variants often incorporate recycled materials, contributing to sustainability. The use of recycled content reduces the demand for virgin materials and minimizes environmental impact, aligning with eco-conscious practices.

4. Versatility in Design

Co-extruded technology allows for greater design flexibility. Manufacturers can experiment with various color options, wood grain patterns, and textures, providing consumers with a wide range of choices to suit their preferences and outdoor aesthetics.

5. Low Maintenance

Co-extruded wood plastic composite flooring requires minimal maintenance compared to traditional wood. The protective outer layer makes it resistant to moisture absorption, reducing the risk of mold, mildew, and rot. Additionally, it eliminates the need for regular staining, sealing, or painting, contributing to a low-maintenance outdoor solution.

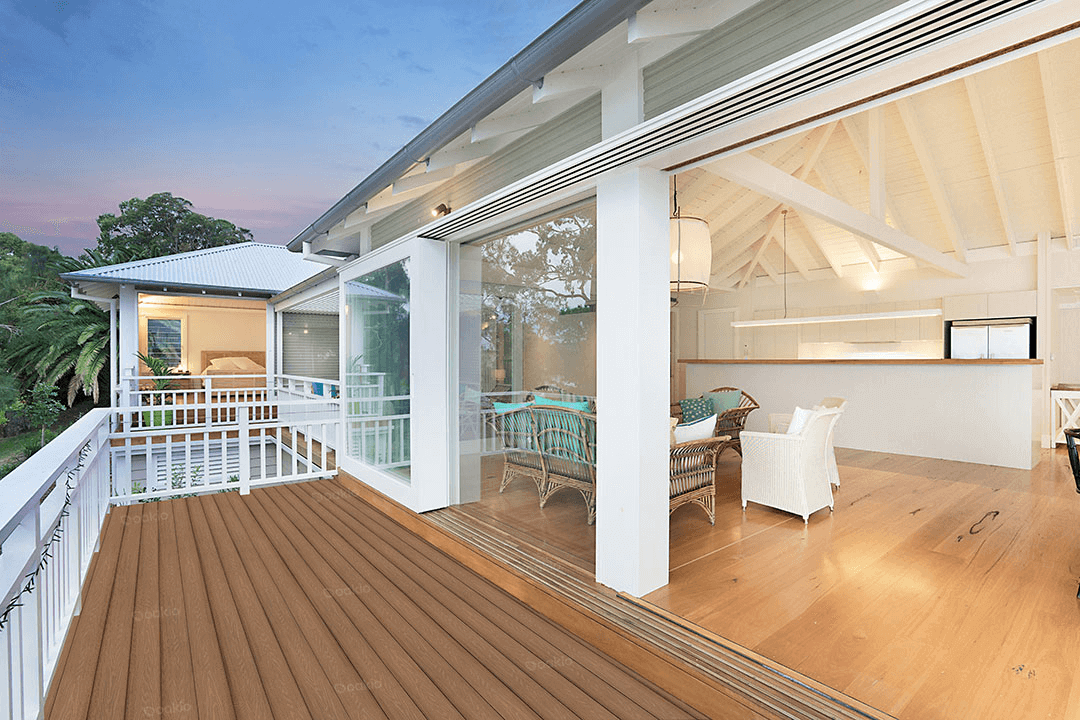

6. Increased Home Value

Installing co-extruded WPC decking can enhance the overall value of a property. Its longevity, low maintenance requirements, and attractive appearance make it an appealing feature for homeowners, potentially increasing the resale value of the home.

Conclusion

Co-extruded wood plastic composite represents a significant advancement in the world of outdoor decking materials. Its multi-layered structure, encompassing a protective outer shell and a resilient core, sets it apart from traditional WPC. The advantages of co-extruded WPC, including enhanced durability, improved aesthetics, and low maintenance, make it a compelling choice for those seeking a long-lasting and visually appealing outdoor solution. As technology continues to evolve, Co-extruded WPC stands as a testament to innovation in the pursuit of sustainable, durable, and aesthetically pleasing outdoor materials.

Trending Reading

What Are the Differences Between the WPC Board and PVC Board?

[2024 Update] How Long Does WPC Decking Last?