Quick Guide: Deck Joist Spacing And Sizing For DIYers

Are you a DIYer building a deck but you’re not sure about the proper deck joist spacing and sizing? Many DIYers are having trouble with these, but it’s understandable—spacing and sizing are both technical and sometimes building codes make it even more complicated.

Choosing the right size and spacing for the joists of your deck is important to ensure it’s safe, sturdy, and would last long. Apart from safety, the right size and spacing would ensure a more uniform look and can improve the overall aesthetics of the deck.

In this guide, we’ll discuss proper deck joist spacing and sizing based on different deck dimensions and features. Let’s get started.

What Is A Deck Joist?

Deck joists are horizontal support structures beneath the boards of your deck. They support the weight of the deck and the users and are also supported by vertical posts. Joists can be made from materials such as pressure-treated wood, engineered wood, and steel.

Think of them as the skeleton of the human body—they hold everything up in your deck and ensure it won’t crumble under the overall weight and pressure of users. Since they’re that important, joists are also subjected to local building codes.

Types of Deck Joists

Here are the different types of deck joists:

- Pressure-treated lumber: It’s the most commonly used deck joist material for its cost-effectiveness and high tensile strength.

- Engineered wood: If you want a material that’s sturdier and more versatile than pressure-treated wood, look to engineered wood—such as LVL (laminated veneer lumber) and I-joists.

- Steel: The strongest material of the three, known for its extremely high tensile strength and superior fire resistance.

READ MORE: Composite Deck Structure: What Are The Parts Of A Deck?

Local Building Codes and Standards

As mentioned, deck joist size and spacing matter from an engineering perspective—they’re support structures after all, and need a stricter code. These codes are meant to make sure the deck you’re building is safe and sound.

If you’re not fully knowledgeable about these codes in general, you can give your local authorities a simple call or email to discuss these, though you may be better off discussing these in person so you can understand more.

Key Considerations in Choosing a Joist

When choosing a joist, you need to account for several factors to ensure and balance optimal structural integrity, aesthetics, and durability. Here are the factors to consider:

1. Deck Shape

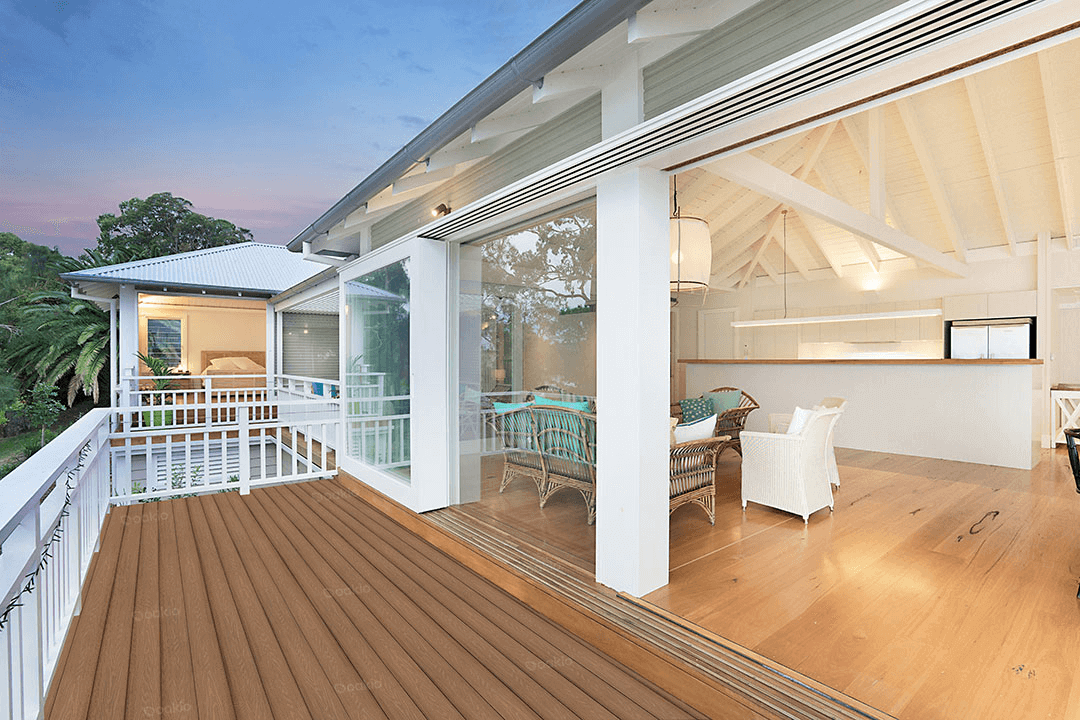

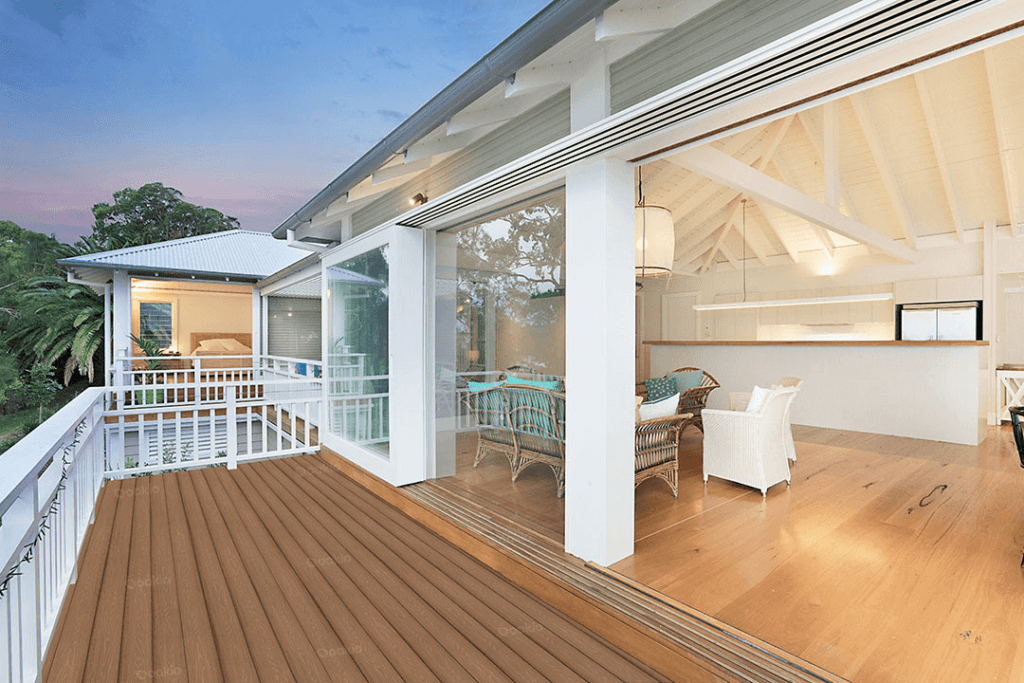

The shape of the deck determines the joist specifications and dimensions. A rectangular deck may require fewer joists since the shape is simple, while complex ones may need more.

2. Position and Placement of Deck

Certain placements and positions can expose your deck to the elements, meaning you’ll need a weather-resistant one. Elevated decks also need higher load-bearing joists, such as steel.

3. Deck Board Layout

The layout of the board determines deck joist spacing and orientation as patterns like diagonal ones require closer spacing to prevent premature sagging, as compared to simpler straight layouts.

4. Deck Span

The span, or the distance between the support beams also affects size and spacing, since longer spans require closely placed joists to maintain optimal structural integrity.

5. Live Load

Live load is the overall weight capacity of the deck, including furniture and people. Standard ones require deck floor joist spacing that can withstand at least 40 pounds per square foot of continuous pressure—simply put, the heavier the load, the thicker and longer the joist should be.

6. Beam Size

Supporting beam sizes can impact joist sizing and spacing. Longer and wider beams allow for longer joist spans and reduce the joists needed.

7. Deck Ledger

The ledger is the part of the deck that attaches to the house—giving the deck stability. If the deck ledger is wider and longer, more and larger deck joist sizes are often needed.

8. Joist Material

Here’s a quick table for better understanding:

| Material | Sizes | Cost |

| Pressure-Treated Wood | 2×6, 2×8, 2×10, 2×12 | Moderate |

| Engineered Wood | LVL: 1 ¾” x 7 ¼” to 1 ¾” x 24”I-Joists: 9 ½”, 11 ⅞”, 14”, 16” | High |

| Steel | Customizable | Very High |

How To Calculate Deck Joist Spacing

While calculating the technical aspects of joist spacing for a deck may seem daunting, you can do it by carefully following these few steps:

Plan Your Deck

Before you go into the calculation, you’ll need to draw a plan for your deck. Make sure it’s as detailed as it can get—including the beam locations, the sizes, and the deck shape you prefer so you can decide the span between the beams where the joists will attach.

We suggest being as thorough as possible with your plans as this can make or break the project if it’s not detailed enough.

Material Matters

The deck material you’ll be choosing can also impact the way the joists should be placed. Heavier and sturdier materials like composites may need closer joist placement to distribute the load better.

The load you’re planning on placing on the deck, such as furniture, also means joists should be placed closer to each other.

Joist Selection

The joist size you prefer also plays a role in determining how much space you should allow between them. Larger and thicker joists can be placed farther from each other than smaller and thinner ones.

Span and Spacing Calculations

In this step, using a deck joist span calculator is recommended. With your plans, materials, and preferred joist size in mind, you can input values into the calculator to make an informed decision. If a calculator seems to not be trustworthy for you, consulting a pro is recommended.

How To Install A Deck Joist

Here comes the exciting part. Follow these steps to properly install and ensure optimal deck joist spacing:

Step 1: Make Sure the Deck Frame is Stable

Start by ensuring the deck frame and ledger are stabilized and tightly attached to your house and supporting posts. All structural vertical posts and horizontal beams should be level to ensure an even deck surface.

Step 2: Use String Lines to Level Joists and Ensure They’re in Plane

Use string lines to ensure the joists are level and in the same plane. Grab one end of the line and stretch it from one end of the deck, all the way to the area where the top of the joists will attach. Adjust if and when necessary to level the surface.

Step 3: Keep Joist Size Consistent

As you install joists, it’s important to keep the sizes as consistent and uniform as possible to ensure equal strength and stability across every part and corner of the deck. Whether you’re using steel, engineered wood, or pressure-treated wood, you need to use the same deck joist size.

Step 4: Ensure Joists are Spaced Adequately

The apple of the eye of this guide, this step should be done to ensure the joists are supporting the deck structure optimally. The standard spacing of joists is 16 inches in the center, but this depends on the decking material and the expected load and all boils down to your decking plan.

Step 5: Install Blocking

A blocking is a piece of wood or a similar material that prevents joists from twisting out of place. In this sense, blocking provides an additional degree of stability. Though it seems blocking is optional in deck construction, they are also under local building codes and are installed in between joists, and are typically placed every 4 to 6 feet between the joists.

Bonus Step: Maintain Deck Framing Condition with Joist Tape

Joist tape provides a moisture barrier for the top of the joists—preventing water penetration and rotting in the first place, and prolonging the overall life of the deck frame. Feel free to use them sparingly.

Helpful Deck Joist Spacing Tips

- Proper Blocking Installation: Use blocking between joists at intervals of 4-6 feet to prevent the joists from twisting laterally and out of place.

- Span Limits: Follow manufacturer guidelines and instructions regarding maximum joist span to prevent deflection and bounce.

- Ensure Impeccable Measurement: Use a measuring tape, a laser measurement tool, or whatever comes in handy to ensure you can maintain perfect spacing and leveling for the deck surface.

- Decking Material Factor: Factor in heavy decking materials or heavy loads and reduce the spacing of the joists as necessary to increase overall deck stability.

- Standard Spacing: Most standard decks have joists that are spaced 16 inches in the center, you can use this as a reference and adjust as necessary according to your plans in mind.

Build Long-Lasting & Sturdy Composite Decks with Oakio!

As a leading WPC innovator and manufacturer, Oakio offers a premium and wide range of composite decking products we’re sure you’ll love for their durability and aesthetics!

With our expertise, you can rest assured you can build your dream deck with confidence, and with the use of our useful tools, such as our decking calculator—you can make informed decisions about your deck size preferences!

Sign up for our newsletter today and get exclusive access to guides like these and get exciting promos and discounts on our composite deck materials!

Trending Reading

What Are the Differences Between the WPC Board and PVC Board?

[2024 Update] How Long Does WPC Decking Last?