Understanding Parts of A Deck: From Substructure to Surface

Building a deck is an excellent way to enhance your outdoor living space, providing a place for relaxation, entertainment, and enjoyment of nature. However, to construct a safe, durable, and aesthetically pleasing deck, it’s crucial to understand its anatomy. Knowing the different parts of a deck and their functions can help you design, inspect, repair, and build your own deck effectively. This guide will take you through the key components of a deck, from the substructure to the surface, highlighting the importance of each part in ensuring the stability and aesthetics of your deck.

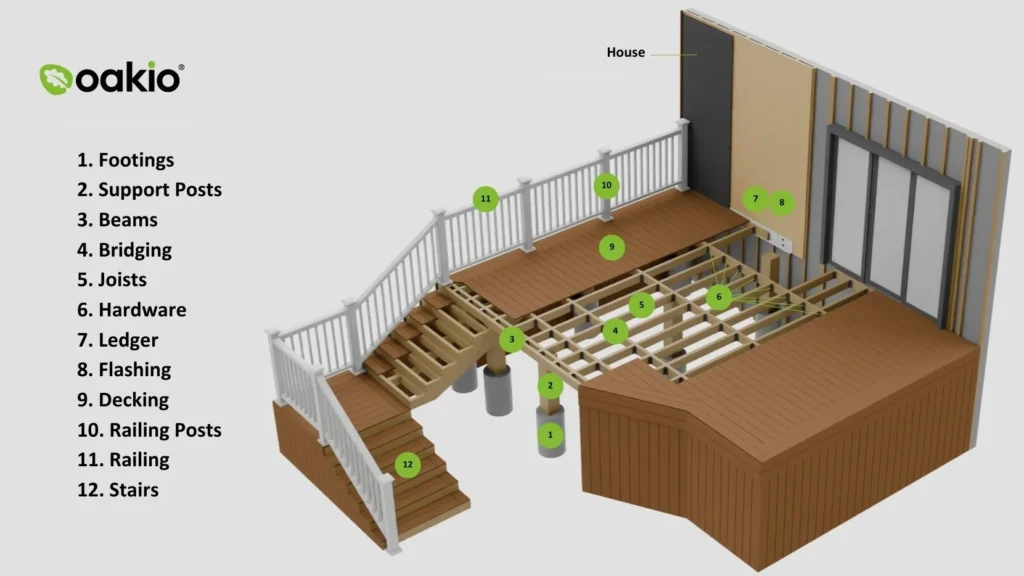

Deck Anatomy Overview

A well-built deck consists of 12 main components that can be categorized into two sections: the substructure and the surface. The substructure serves as the foundation and support system, while the surface provides the visible and usable top layer of the deck. Each component plays a vital role in maintaining the deck’s integrity, safety, and overall appearance.

Substructure Components

The substructure is the backbone of any deck. It is responsible for supporting the deck’s weight and ensuring its stability over time. Understanding the substructure components is essential for building a safe and durable deck.

1. Footings

Footings are the foundational elements that anchor the deck to the ground. Typically made from concrete, footings are poured into holes dug in the ground and are crucial for distributing the deck’s load over a larger surface area. This helps prevent the deck from sinking or shifting, especially in regions with varying weather conditions. In colder climates, footings must extend below the frost line to prevent movement caused by freezing and thawing cycles.

2. Support Posts

Support posts elevate the deck above ground level and are connected to the footings using metal brackets. These posts are critical for holding up the deck frame and transferring the load from the beams and joists to the footings. The height and spacing of support posts depend on the deck’s design and local building codes. For taller decks or those built on slopes, additional bracing may be required to prevent buckling under heavy loads.

3. Beams

Beams, or girders, are horizontal support elements that run parallel to the deck’s ledger board or the outer rim joists. Beams provide critical support for the joists and deck surface, ensuring the structure remains stable and secure. Depending on the size of the deck and the spacing of the joists, multiple beams may be required. Beams are typically constructed from treated wood or steel, depending on the desired durability and load-bearing capacity.

4. Joists

Joists are one of the most prominent parts of a deck’s substructure. These horizontal elements run perpendicular to the beams and provide support for the decking boards. Joists are usually spaced 16 inches on center, although this spacing can be adjusted based on the type of decking material, the pattern of the deck boards, and the desired foot feel. For instance, closer joist spacing, such as 12 inches on center, is recommended for diagonal decking or heavier decking materials.

5. Blocking and Bridging

Blocking and bridging involve placing small pieces of wood between joists to prevent them from twisting and to add lateral stability to the deck structure. This component is essential for maintaining the alignment and integrity of the joists over time. Blocking is typically installed in a staggered pattern every 4 to 6 feet along the joists. Proper installation of blocking and bridging ensures that the deck remains level and free from structural issues caused by joist movement.

6. Ledger Board

The ledger board is a horizontal piece of wood or metal that secures the deck to an adjoining structure, such as a house. This component transfers some of the deck’s load to the building’s frame, providing additional support. Proper installation of the ledger board is crucial, as failure to securely attach it can lead to the deck pulling away from the house, compromising its stability. Regular inspections should be conducted to ensure the ledger board is free from rot and securely fastened.

7. Hardware

Hardware encompasses all the connectors, fasteners, and brackets used in deck construction. This includes joist hangers, lag screws, bolts, and nails, all of which play a critical role in holding the deck components together. The hardware must be suitable for outdoor use, corrosion-resistant, and properly sized to ensure the deck’s structural integrity. Using incorrect or low-quality hardware can compromise the safety and longevity of the deck.

8. Flashing

Flashing is an essential protective component installed to prevent water from seeping into the areas where the deck meets the house. Typically made from metal or vinyl, flashing is placed over the ledger board to direct water away from the building and prevent moisture-related damage. Installing flashing correctly is vital to prevent rot and decay in both the deck and the adjoining structure.

Deck Surface Components

The deck surface includes all the visible elements of the deck that contribute to its functionality and aesthetic appeal. These components are not only important for the deck’s appearance but also for ensuring safety and comfort.

1. Decking Boards

Decking boards form the top surface of the deck and are the most visible part of the structure. Available in a variety of materials, including natural wood, composite, and PVC, decking boards can be customized to match your desired look and feel. The installation of decking boards requires careful consideration of spacing and fastening methods to ensure a secure and durable surface. Proper installation also prevents issues such as warping, splitting, and moisture damage. If you are searching for durable decks, Oakio Composite decking will be a great choice.

2. Railing Posts

Railing posts are vertical supports that hold the railing system in place. Typically made from wood or metal, these posts are secured to the deck frame or surface and are essential for ensuring the safety of the deck. The choice of materials and the design of the railing posts can greatly affect the overall aesthetic of the deck, with options ranging from classic wood to sleek, modern metal designs.

3. Railing

Railings are critical for safety, especially on decks that are more than 30 inches off the ground. The railing system consists of a top rail, bottom rail, and infill, which can be made from various materials such as wood, metal, glass, or cable. The choice of railing design can significantly impact the deck’s appearance, providing either a traditional or contemporary look. Proper installation of railings is essential to meet safety standards and building codes.

4. Stairs

Stairs provide access to the deck from the ground or other levels. The design of the stairs can vary widely based on the deck’s height, layout, and personal preference. Options include straight stairs, L-shaped stairs, spiral stairs, and more. It’s important to ensure that stair design and construction comply with local building codes, as this will affect the safety and usability of the deck.

Practical Tips for Deck Construction and Maintenance

Regular inspections and maintenance are key to preserving the integrity and appearance of your deck. Check all components for signs of wear, damage, or rot, especially the substructure elements that are not visible from above. Always use high-quality, corrosion-resistant hardware and ensure all connections are secure. Lastly, consult local building codes before starting any deck project to ensure compliance with safety regulations and standards.

Trending Reading

What Are the Differences Between the WPC Board and PVC Board?

[2024 Update] How Long Does WPC Decking Last?