Antibacterial Wood Plastic Composite Material Technology

In the early days of production and application of plastic wood composites, it is believed that using plastic substations buried by plant fiber fillers can make the composite feature protection against water, fungal and corrosion, even if no antibacterial agents are added to the composite materials. However, with the application and development of plastic wood composite materials, it has been found that the anti-corrosion antibacterial properties of plastic wood composites are not as good as expected. Many moldy and decaying fungi will be harmful to plastic wood composites, infesting bacteria and even degrading plastic wood composites.

The Evolution of Wood-Plastic Composites

In the nascent stages of wood-plastic composite (WPC) production and usage, it was posited that blending plastic with plant fiber fillers could imbue the composite with inherent resistance to moisture, decay, and fungal growth, even in the absence of antimicrobial additives. This belief underscored the perceived durability and eco-friendliness of WPC, positioning it as an ideal material for various applications. Yet, as the deployment and exploration of WPC materials advanced, their expected resilience to microbial threats fell short. It became evident that mold, decay fungi, and bacteria could indeed compromise WPC, affecting its integrity and longevity.

Rising Standards and Expectations for WPC

Moreover, as societal living standards escalate, so too do expectations for WPC functionalities. There’s a growing demand for mold-resistant WPC in health-sensitive environments such as hospitals, restrooms, and public parks. Additionally, there’s a call for WPC products that possess inherent antibacterial properties to safeguard public health. Addressing this, the strategic incorporation of antibacterial agents into WPC formulations can yield significant benefits. Enhanced WPCs, equipped with targeted antimicrobial action, can dramatically extend material lifespan, boost market competitiveness, and facilitate the expansion into sectors with stringent hygiene standards. This not only meets evolving societal demands but also promotes sustainable consumption and yields superior economic returns.

Innovations in Antimicrobial Agents for WPC

Antibacterial additives are categorized into inorganic, organic, polymer-based, and compound antimicrobial agents, each with unique mechanisms and efficacies against specific pathogens. The quest to augment WPC’s resistance to decay and bacteria has spurred global research into diverse antimicrobial strategies, aiming to refine the composite material’s durability and health safety profile.

The Future of WPC: Health-Conscious and Eco-Friendly Materials

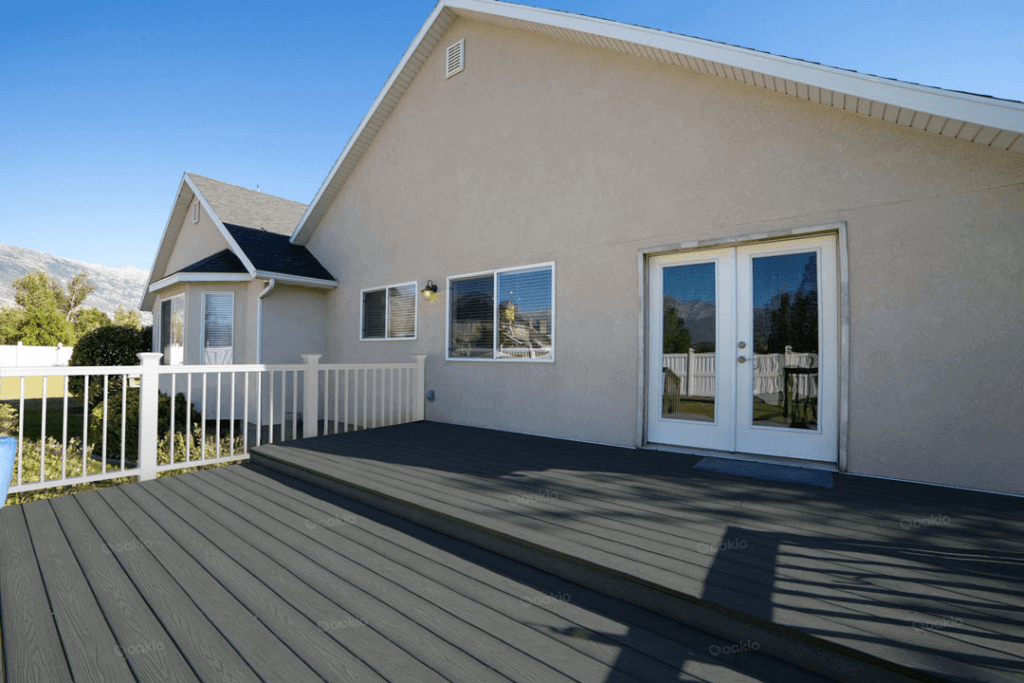

In the current climate of heightened health consciousness, the demand for materials that are not only safe and eco-friendly but also intrinsically antibacterial is accelerating. This trend towards materials that can actively combat microbial growth, like enhanced WPC, is becoming a staple in furniture and architectural design, both indoors and outdoors. Given the varied efficacy and characteristics of different antimicrobial agents, the resultant protective qualities of WPC vary, highlighting the need for meticulous selection based on the intended application and environmental exposure.

By delving into the ongoing research on antimicrobial WPC, it’s clear that polymer and compound antimicrobial agents are increasingly preferred for their robust antibacterial properties. These advancements in WPC technology underscore a commitment to improving material safety, environmental sustainability, and the overall healthfulness of living spaces, aligning with contemporary demands for cleaner, greener, and safer materials.

Trending Reading

What Are the Differences Between the WPC Board and PVC Board?

[2024 Update] How Long Does WPC Decking Last?