Enhancing Acoustic Insulation with WPC Integrated Wall Systems

WPC (Wood-Plastic Composite) materials are transforming modern construction, especially in lightweight steel structures. WPC integrated wall systems, used for exterior cladding, interior panels, and structural support, enhance strength, seismic resistance, and construction speed. However, addressing soundproofing challenges is crucial for advancing WPC buildings further.

Challenges in Acoustic Insulation for WPC Buildings

Acoustic insulation is a key factor in building comfort, particularly for lightweight steel frame constructions. WPC walls, while strong and durable, often require enhanced noise reduction measures to meet residential and commercial needs. Effective soundproofing involves controlling gaps, minimizing rigid connections, and increasing wall density.

Research shows that WPC materials, when compared to traditional lightweight steel frames, offer improved sound insulation due to their elastic-plastic properties. This makes WPC ideal for modern wall systems aimed at reducing noise pollution.

Soundproofing Techniques for WPC Walls

1. Wall Panel Thickness:

- Using thicker WPC panels significantly improves noise reduction. For instance, a 50mm WPC exterior panel increases sound insulation by 1.7dB for traffic noise compared to a 20mm panel, which offers a 0.8dB improvement.

- Surrounding wall panel edges with proper seals further boosts soundproofing by up to 0.5dB.

2. Elastic Sealing Strips:

- Incorporating flexible sealing strips with materials like acoustic cotton and non-woven fabrics enhances sound absorption. This method can increase sound insulation by 3.6dB for traffic noise and 3.1dB for general noise.

3. Interior Wall Design:

- While thinner interior panels contribute less to soundproofing, using elastic spacers at connection points can address weak spots and improve overall performance.

Benefits of WPC for Soundproof Wall Systems

WPC integrated walls not only excel in acoustic insulation but also offer additional advantages:

- Sustainability: WPC materials are eco-friendly, reducing the need for traditional wood and promoting energy-efficient construction.

- Durability: Resistant to moisture, pests, and aging, WPC walls maintain their performance in various conditions.

- Industrialization: Their compatibility with lightweight steel frames enables faster, more efficient building processes.

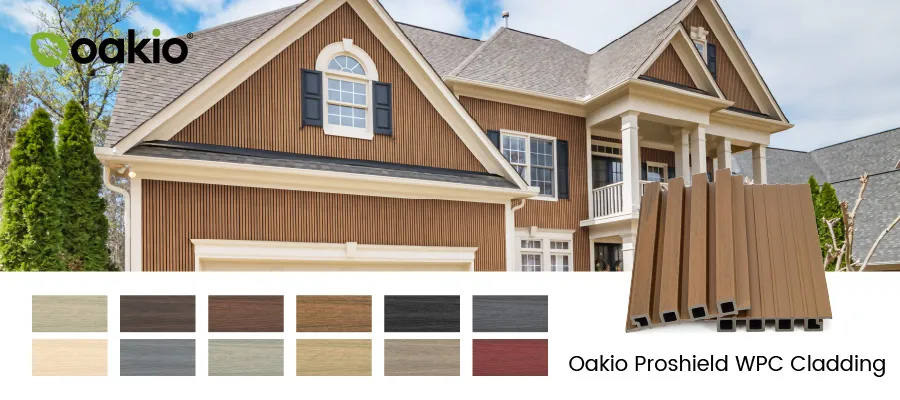

Additionally, WPC wall systems elevate the aesthetic appeal of modern constructions with customizable textures and finishes, making them ideal for residential and commercial applications.

Conclusion:

WPC integrated wall systems are revolutionizing soundproof construction by offering enhanced acoustic insulation, durability, and sustainability. By adopting techniques like thicker panels, flexible sealing strips, and optimized interior designs, WPC walls address noise reduction challenges while setting new standards in eco-friendly building solutions.

Transform your next project with Oakio’s range of innovative WPC wall systems—engineered for superior performance and sustainable living. Visit us today to learn more!

Trending Reading

What Are the Differences Between the WPC Board and PVC Board?

[2024 Update] How Long Does WPC Decking Last?